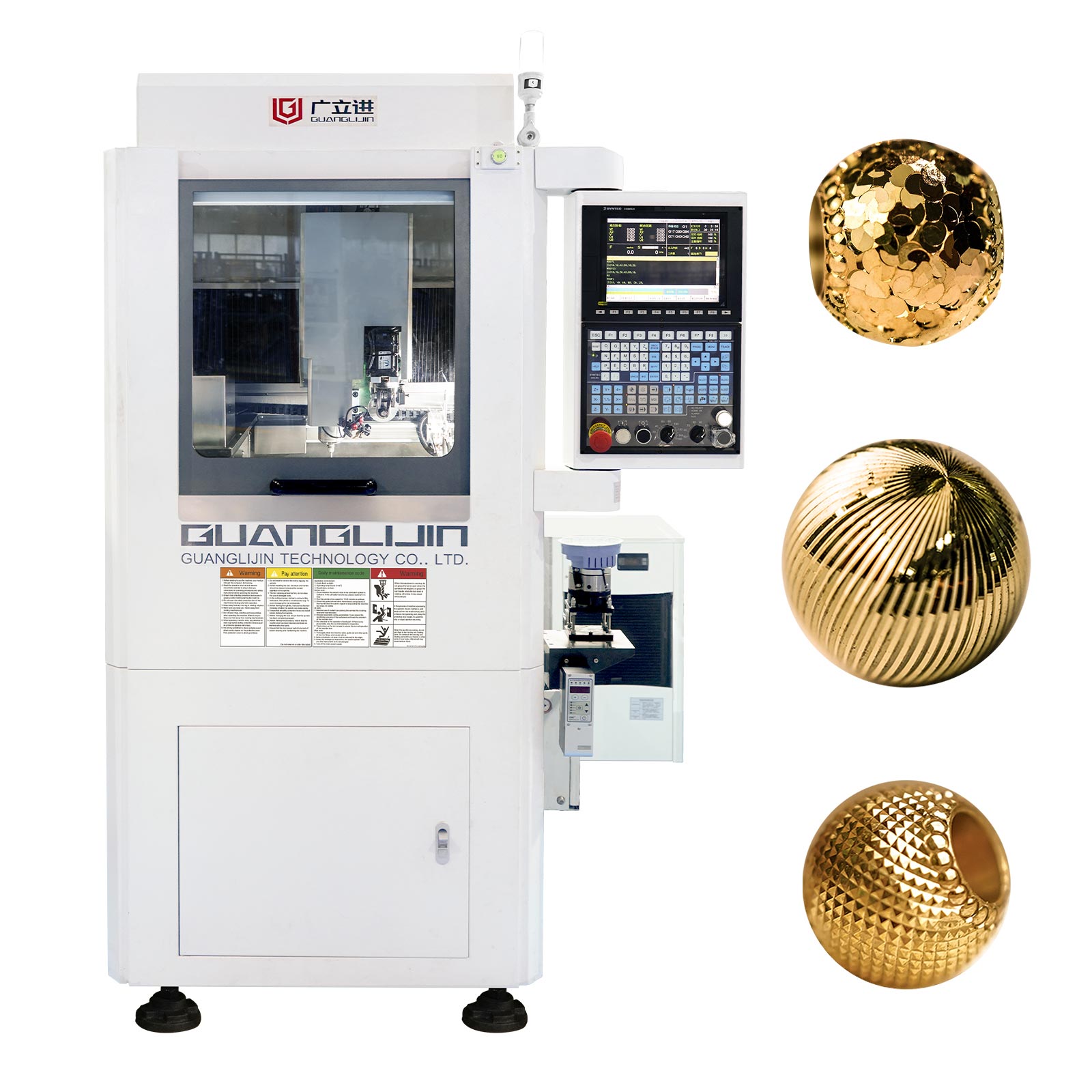

Fully Automatic CNC Jewelry Lathe | Precision Engraving & Ultrasonic Process All-in-One Machine

Key Features

High-Precision Engraving Process

Equipped with 10,000 RPM high-speed electric spindle and multi-axis linkage system (4th/5th/6th axis) for intricate pattern carving

Ultra-high precision ±0.003mm, featuring German-original guide rails + Taiwan Syntec CNC system for flawless detailing

Ultrasonic Precision Machining

Integrated ultrasonic vibration tool head, ideal for hard metals (titanium steel, tungsten steel) and gemstone setting

Reduces material stress, preventing deformation or cracks caused by traditional processing

Fully Automated Production

7-station tool changer with 5-second quick tool switching, supporting engraving, beading, and polishing

Vibration feeder + pneumatic feeding for unmanned continuous processing

Core Specifications

Spindle: 3.7KW pneumatic spindle (ultrasonic module optional)

Control System: Taiwan Syntec 10.4″ touchscreen CNC

Precision: Repeat positioning accuracy ±0.003mm, engraving cutter diameter φ70mm

Automation: SMC pneumatic (vacuum suction) feeding + CCD vision positioning (optional)

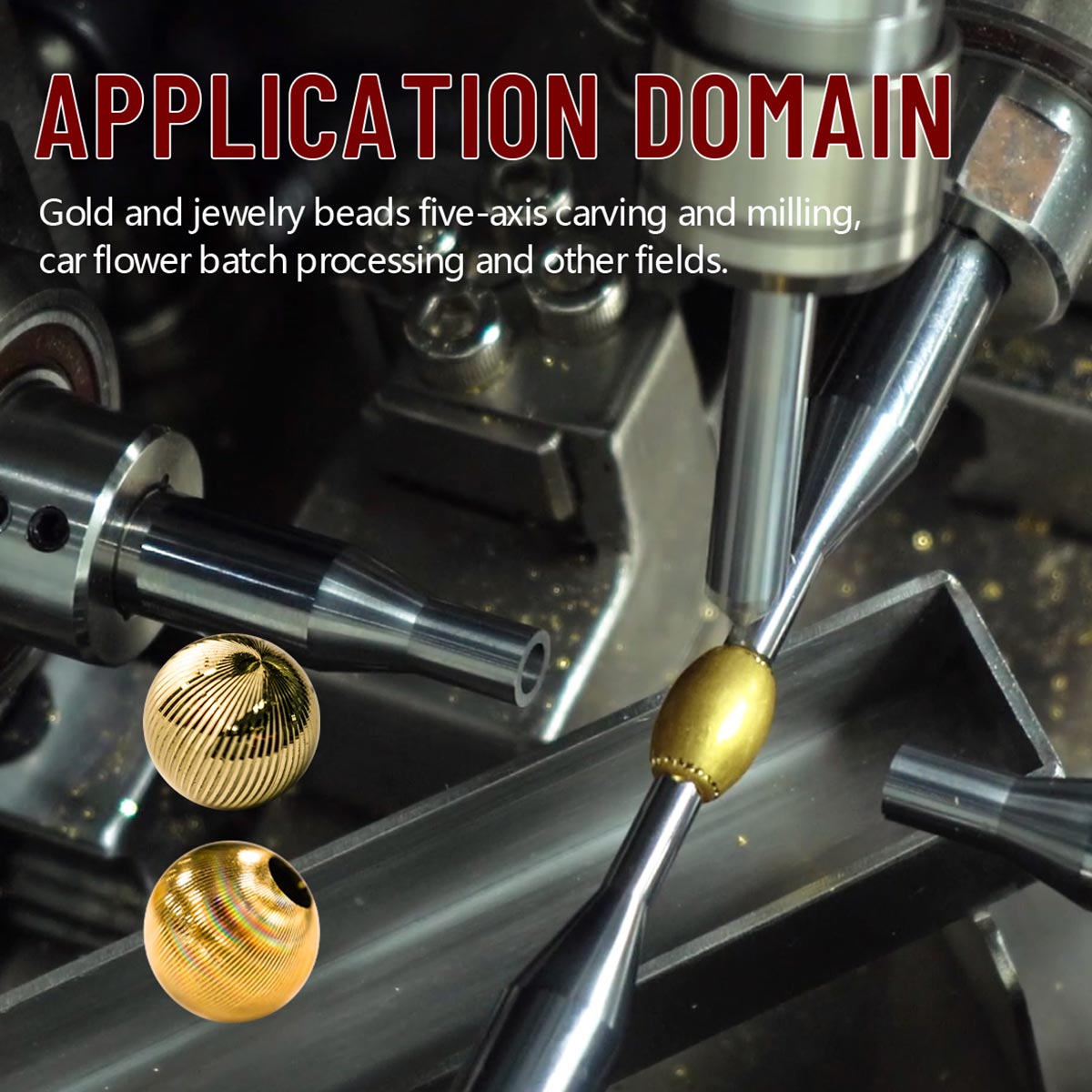

Applications

Luxury Jewelry: Necklace engraving, luxury brand logo carving

Hard Materials: Precision machining of titanium steel/tungsten gold bracelets

Customization: Signature engraving, complex texture batch production

Our Advantages

50% Efficiency Boost: Automatic tool change + continuous feeding, completing 300+ standard workpieces in 8 hours

Wide Compatibility: Supports gold/platinum/titanium alloy/ceramics, and more

Process Upgrade: Combines traditional lathe + ultrasonic technology to solve hard material machining challenges

Technical Parameters:

| No. | Item | Details | |

| 1 | B axis reducer | Japan | Rated torque 15.3N.m, Instaneous max. torque 53.5N.m, Rated speed 250 rpm, max. speed 500 rpm |

| 2 | W axis spindle | servo motor | max. 10000rpm, dia. of round cutter: 70mm |

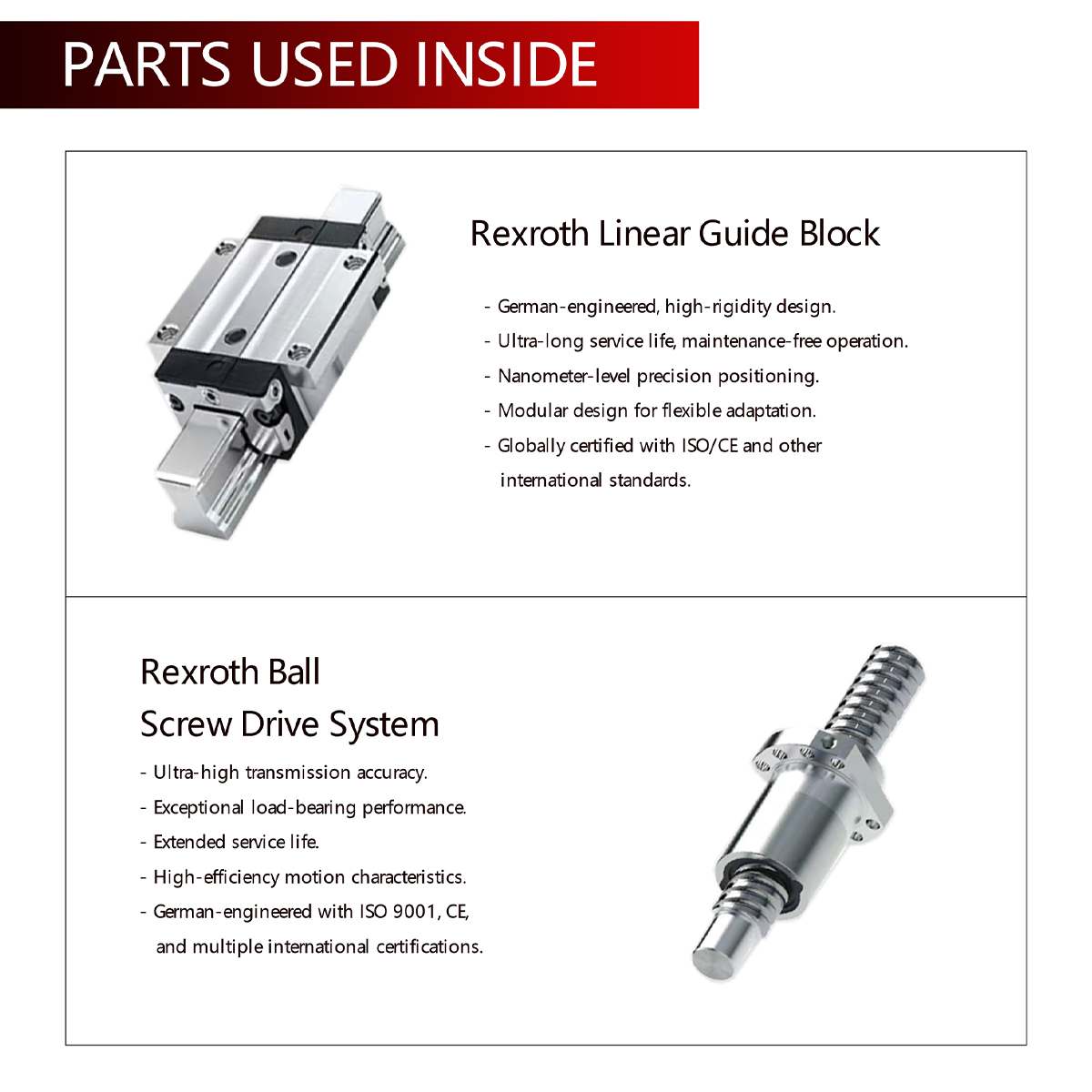

| 3 | Transmission components | Rexroth, Germany | Repeatability: +/-0.005mm |

| 4 | Operation | SYNTEC system | 220MB-10.4 inch screen operation box, max. extending 500mm on width at left side |

| 5 | Servo motor | 100W/400W/750W | |

| 6 | Spindle | air-operated | 3.7kw, max. speed 45000 rpm water cooling with flow-alarm |

| 7 | Tool magazine | Up to 7 tools | |

| 8 | Bead rolling | servo-drive | 250 rpm to 500 rpm |

| 9 | Tool holder | Penumatic driving | HSK E25 |

| 10 | Collet chuck | ER-16 | |

| 11 | Lubrication | Timing automatic oiling | |

| 12 | Working flatness | +/-0.015mm | |

| 13 | X axis stroke | 195mm | |

| 14 | Y axis stroke | 85mm | |

| 15 | Z axis stroke | 130mm | |

| 16 | Body weight | 1.0 tons | |

| 17 | Layout (mm) | main body | 1100 width*1200 depth*2400 height |

| 18 | Power requirement | 380v/50hz | |

Support and Services:

Technical support

Installation

Training

Maintenance

Troubleshooting

Software upgrade

Packing and Shipping:

Fumigation wooden case by sea or by air

FAQ:

Q: Are you a dealer or manufacturer?

A: We, Guanglijin, is a manufacturer of CAD/CAM CNC machine with over 20 years experience.

Q: Where are you from?

A: We are from Shenzhen China, one of the most creative city in the world.

Q: Do you provide overseas support or service?

A: Yes, we have a technican team which can travel abroad to do global service and support.

Q: Does this machine come with any certification?

A: Our machines are CE certificated.