Product Features:

This high-performance jewelry manufacturing machine is designed for precision machining of small, intricate parts, offering exceptional accuracy, stability, and efficiency.

Key Features

-

Industry-Specific Design

-

Optimized for precious metal processing with material utilization rate exceeding 99.95%

-

Ideal for precision machining of gold, platinum, and other precious metals

-

-

Outstanding Mechanical Performance

-

Monolithic cast iron construction ensures vibration damping and long-term accuracy

-

4th/5th axes equipped with Japanese precision reducers (±0.003mm positioning accuracy)

-

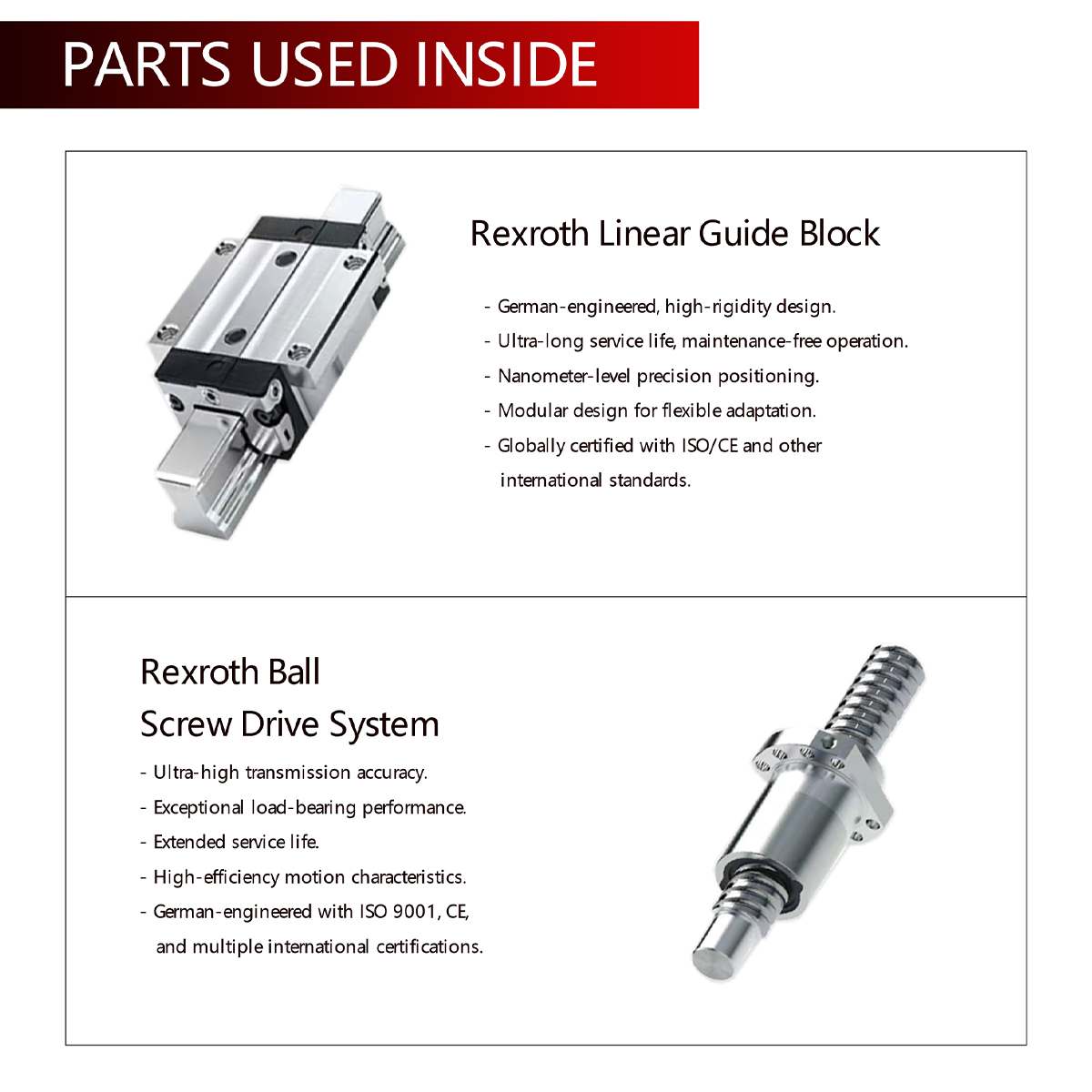

German Rexroth ball screws and linear guides for superior motion control

-

-

Intelligent Machining System

-

Lenake intelligent control system

-

10.4″ industrial touchscreen for user-friendly operation

-

Fully enclosed servo-driven tool magazine (12 stations) with 5-6 second tool change

-

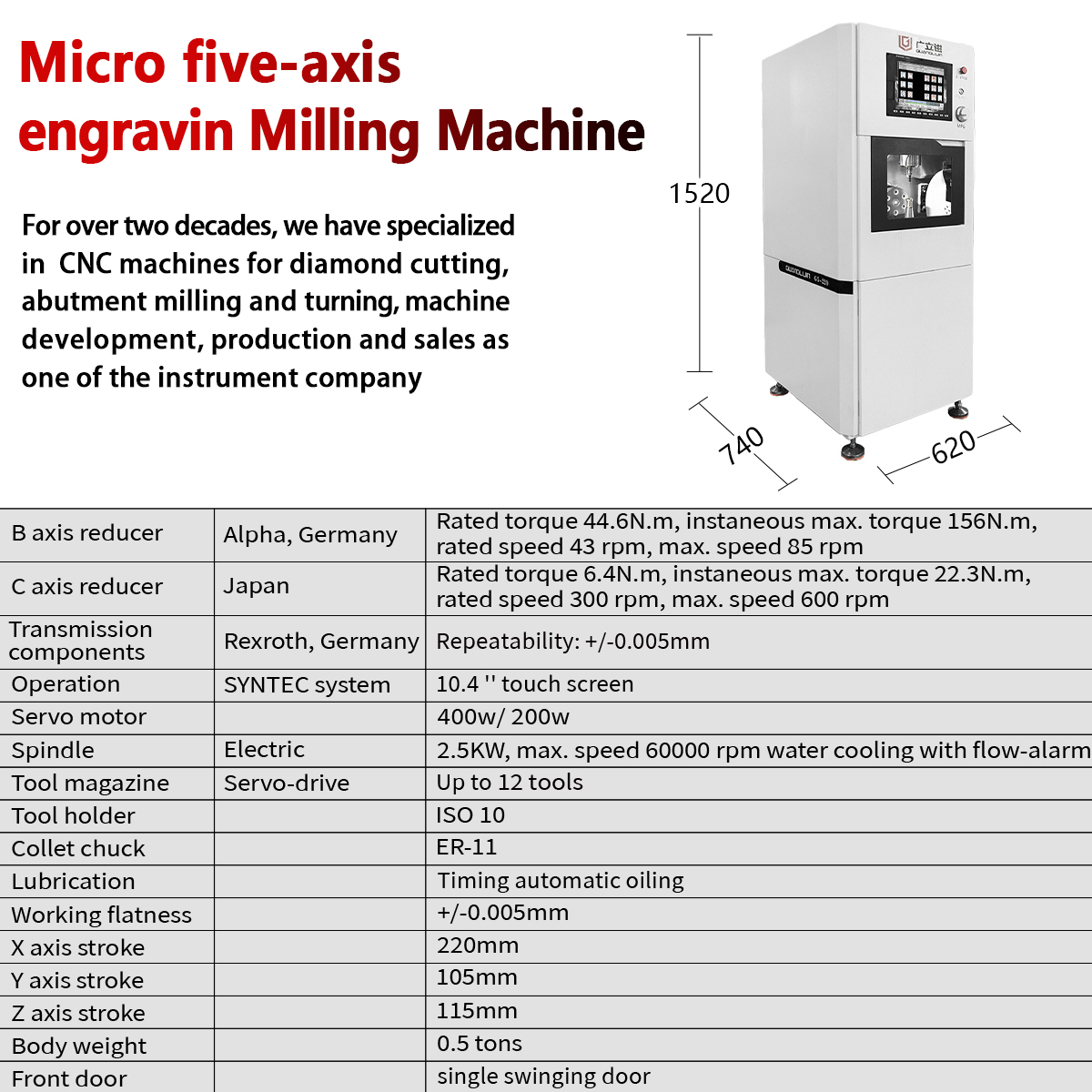

Technical Specifications

-

Spindle Speed: 60,000 RPM (water-cooled)

-

Positioning Accuracy: ±0.005mm

-

Working Travel: X-220mm / Y-105mm / Z-115mm

-

Machine Dimensions: 620×740×1520mm (W×D×H)

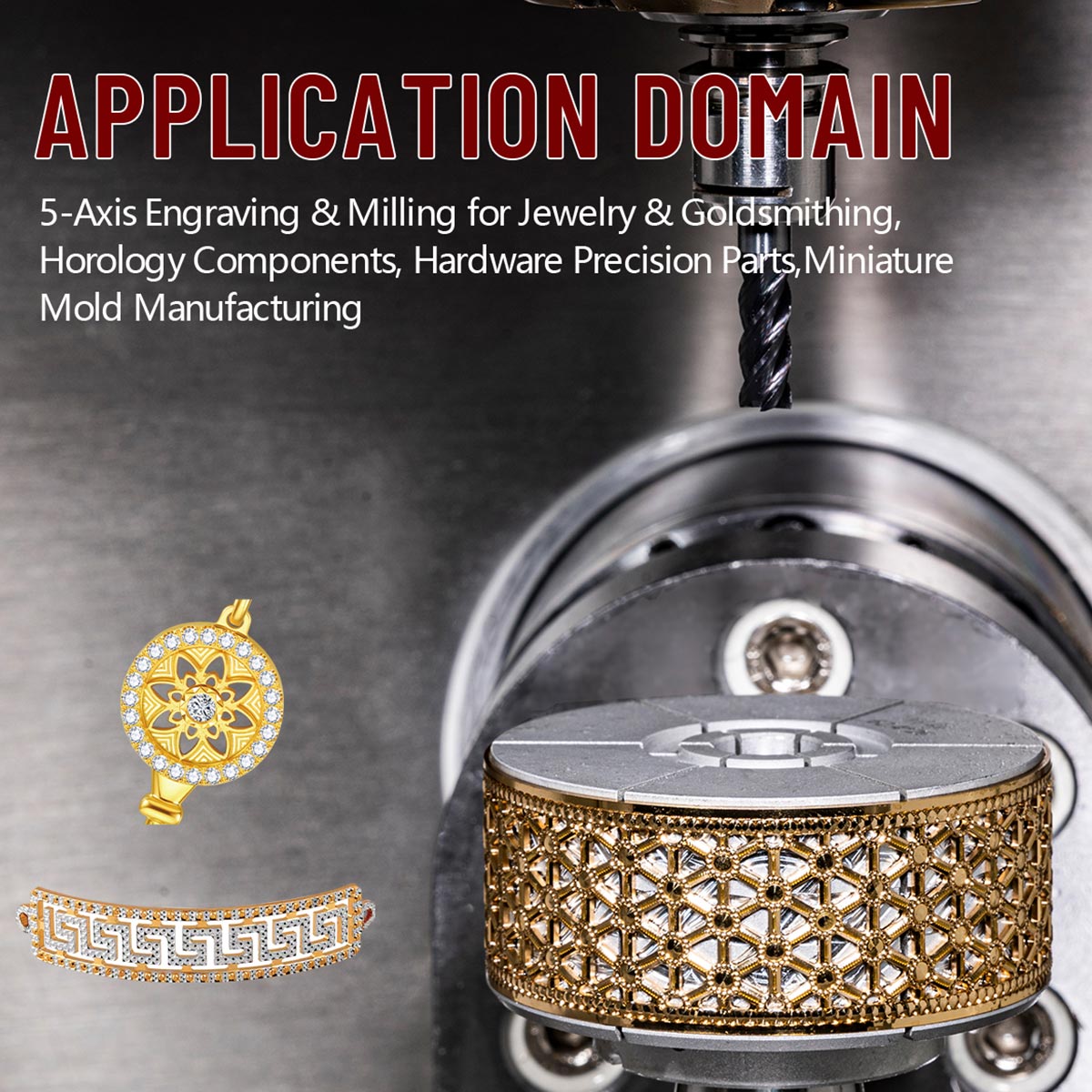

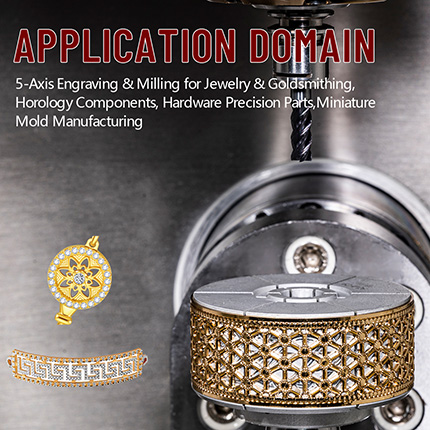

Applications

-

Jewelry manufacturing (rings, pendants, bracelets, etc.)

-

Precision components in precious metals

-

Suitable for jewelry workshops, manufacturing centers, and high-end customization stores

Note: Operates on 220V/50Hz power supply. Machine weight: 500kg. Includes safety doors and automatic lubrication system.

Optional configurations available for specific processing requirements.

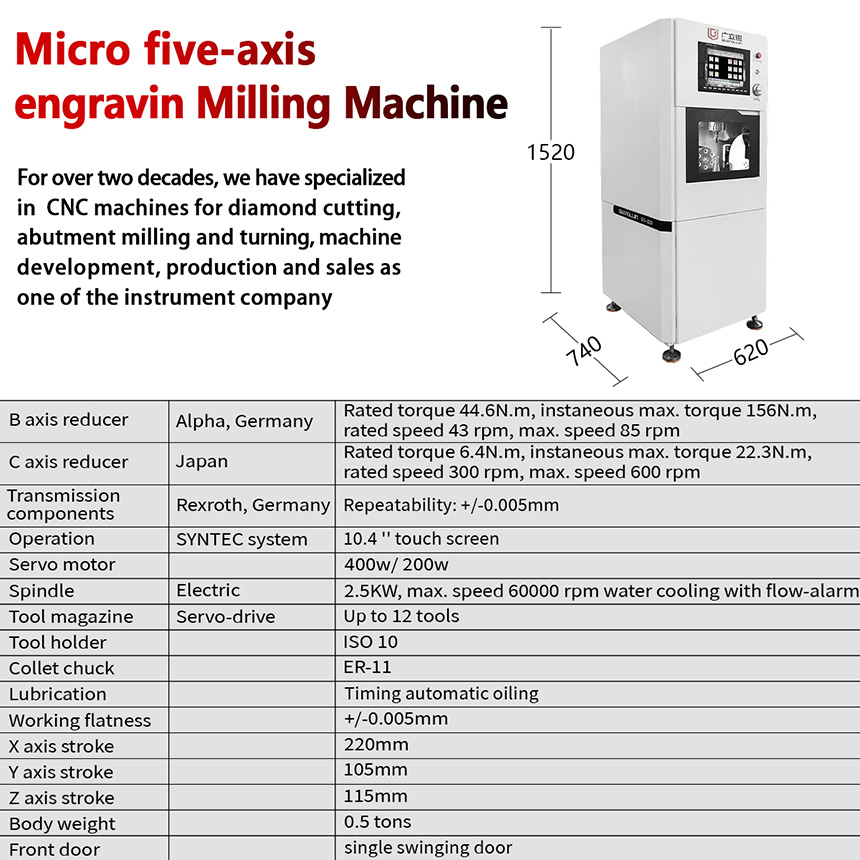

Technical Parameters:

| No. | Item | Details | |

| 1 | B axis reducer | Alpha, Germany | Rated torque 44.6n.m, Instaneous max. torque 156n.m, Rated speed 43 rpm, max. speed 85 rpm |

| 2 | C axis reducer | Japan | Rated torque 6.4n.m, Instaneous max. torque 22.3n.m, Rated speed 300 rpm, max. speed 600 rpm |

| 3 | Transmission components | Rexroth, Germany | Repeatability: +/-0.005mm |

| 4 | Operation | SYNTEC system | 10.4” touch screen |

| 5 | Servo motor | 400w/ 200w | |

| 6 | Spindle | electric | 2.5kw, max. speed 60000 rpm water cooling with flow-alarm |

| 7 | Tool magazine | servo-drive | Up to 12 tools |

| 8 | Tool holder | ISO 10 | |

| 9 | Collet chuck | ER-11 | |

| 10 | Lubrication | Timing automatic oiling | |

| 11 | Working flatness | +/-0.005mm | |

| 12 | X axis stroke | 220mm | |

| 13 | Y axis stroke | 105mm | |

| 14 | Z axis stroke | 115mm | |

| 15 | Body weight | 0.5 tons | |

| 16 | Front door | single swinging door | |

| 17 | Layout (mm) | main body | 620 width*740 depth*1520 height |

| 18 | Power requirement | 220v/50hz | |

Support and Services:

Technical support

Installation

Training

Maintenance

Troubleshooting

Software upgrade

Packing and Shipping:

Fumigation wooden case by sea or by air

FAQ:

Q: Are you a dealer or manufacturer?

A: We, Guanglijin, is a manufacturer of CAD/CAM CNC machine with over 20 years experience.

Q: Where are you from?

A: We are from Shenzhen China, one of the most creative city in the world.

Q: Do you provide overseas support or service?

A: Yes, we have a technican team which can travel abroad to do global service and support.

Q: Does this machine come with any certification?

A: Our machines are CE certificated.