Product Description:

Dual-Station Synergy Technology

Integrated with a high-speed belt-driven texturing head on a precision 5-axis machine base, enabling simultaneous engraving and texturing operations.

Dual independent drive systems achieve uninterrupted machining mode switching, boosting efficiency by 300%.

Dynamic Continuous Texturing Process

Belt transmission system supports 0.1-second rapid directional reversal, realizing seamless continuous engraving of complex patterns (curves, waves, spirals, etc.).

Compatible with 0.05-3mm texturing cutters for high-end jewelry effects: micro-carved textures, geometric arrays, gradient light/shadow.

Efficiency Revolution

Single-piece texturing time reduced from 30 minutes to 90 seconds – 15x daily productivity increase.

Craftsmanship Breakthrough

Achieves multi-dimensional composite patterns unattainable by manual techniques (e.g., intertwined vines, dynamic halos, micro-pavé backgrounds).

Cost Optimization

70% reduction in tool-change/alignment calibration waste, with precious metal scrap rates decreasing by 45%.

Technical Parameters:

| No. | Item | Details | |

| 1 | B axis reducer | Alpha, Germany | Rated torque 44.6n.m, Instaneous max. torque 156n.m, Rated speed 43 rpm, max. speed 85 rpm |

| 2 | C axis reducer | Japan | Rated torque 6.4n.m, Instaneous max. torque 22.3n.m, Rated speed 300 rpm, max. speed 600 rpm |

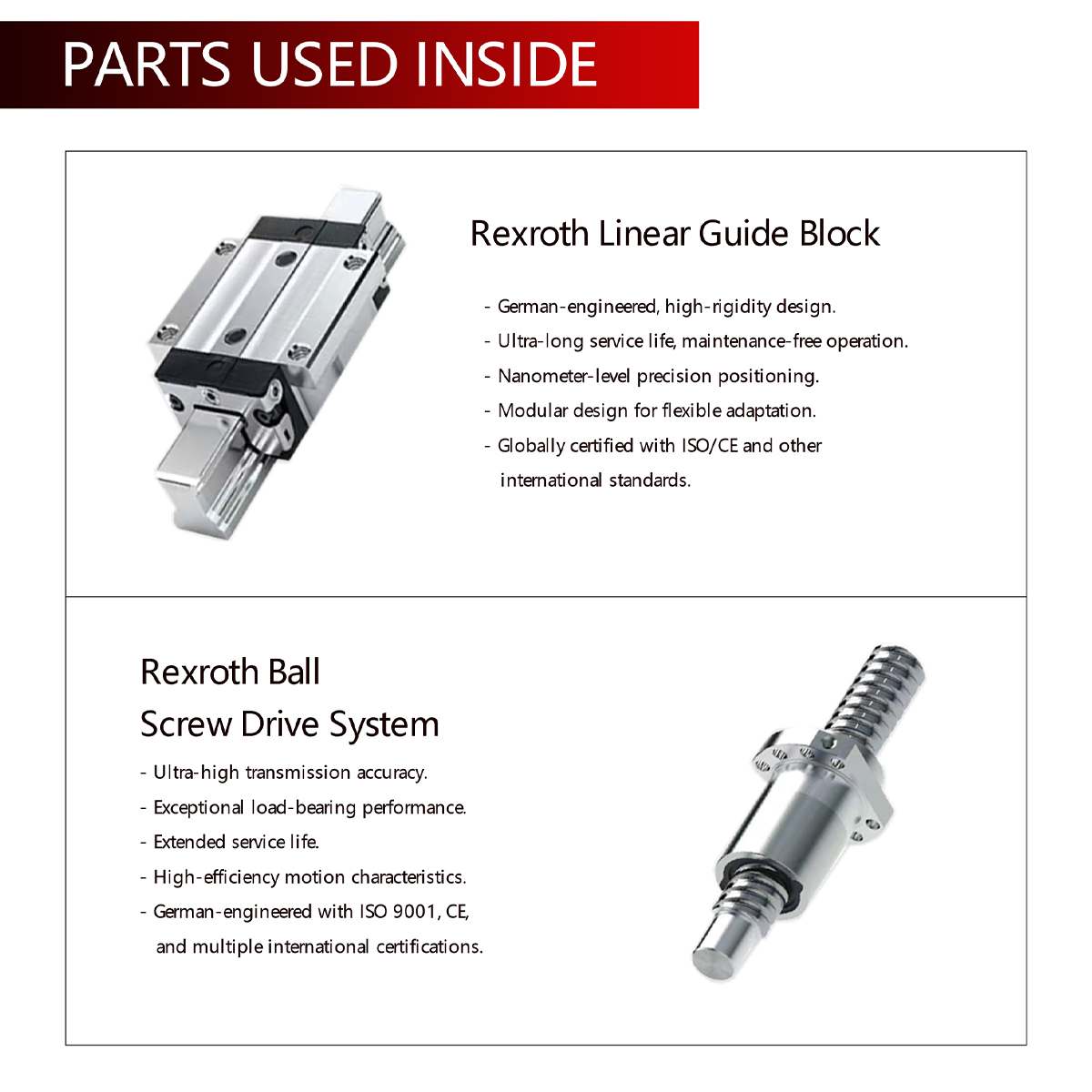

| 3 | 6th axis | Rexroth, Germany | Repeatability: +/-0.005mm |

| 4 | 7th axis spindle | servo motor | max. 10000rpm, max. dia. of round cutter: 60mm min. dia. of round cutter: 40mm |

| 5 | Transmission components | Rexroth, Germany | Repeatability: +/-0.005mm |

| 6 | Operation | SYNTEC system | 10.1” touch screen |

| 7 | Servo motor | 400w/ 200w | |

| 8 | Main spindle | electric | 2.5kw, max. speed 60000 rpm water cooling with flow-alarm |

| 9 | Tool magazine | servo-drive | Up to 12 tools |

| 10 | Tool holder | ISO 10 | |

| 11 | Collet chuck | ER-11 | |

| 12 | Lubrication | Timing automatic oiling | |

| 13 | Working flatness | +/-0.005mm | |

| 14 | X axis stroke | 300mm | |

| 15 | Y axis stroke | 105mm | |

| 16 | Z axis stroke | 115mm | |

| 17 | Body weight | 0.6 tons | |

| 18 | Front door | single swinging door | |

| 19 | Layout (mm) | main body | 700 width*880 depth*1560 height |

| 20 | Power requirement | 220v/50hz | |

Support and Services:

Technical support

Installation

Training

Maintenance

Troubleshooting

Software upgrade

Packing and Shipping:

Fumigation wooden case by sea or by air

FAQ:

Q: Are you a dealer or manufacturer?

A: We, Guanglijin, is a manufacturer of CAD/CAM CNC machine with over 20 years experience.

Q: Where are you from?

A: We are from Shenzhen China, one of the most creative city in the world.

Q: Do you provide overseas support or service?

A: Yes, we have a technican team which can travel abroad to do global service and support.

Q: Does this machine come with any certification?

A: Our machines are CE certificated.